OUR PARTNERS

Who We Partner With

Derrick Corporation is established as a world leader in the development and implementation of innovative cost-effective technologies and processes in the field of mineral, chemical and waste processing. Among the cutting-edge innovations include Hi-G Dewatering and Fines Recovery System, SuperStack Highest Capacity Fine Wet Screening, and G-Vault Urethane Interstage Screening.

Products:

Stack Sizer

- The Derrick® Stack Sizer® packs the performance of five screening machines into one compact system, standing just 5.3 meters tall. With five individual decks stacked vertically and running in parallel, it delivers exceptional capacity and efficiency—all within a small footprint. This high-productivity machine offers low operating and maintenance costs; quick and easy servicing and; long-lasting durability. Its rubber-lined repulp trough and continuous spray bar ensure smooth undersize separation without clogging. Fitted with Derrick® Polyweb® urethane screens, it combines lightweight design, anti-blinding technology, and high performance, with screen life lasting 6 to 12 months and easy installation.

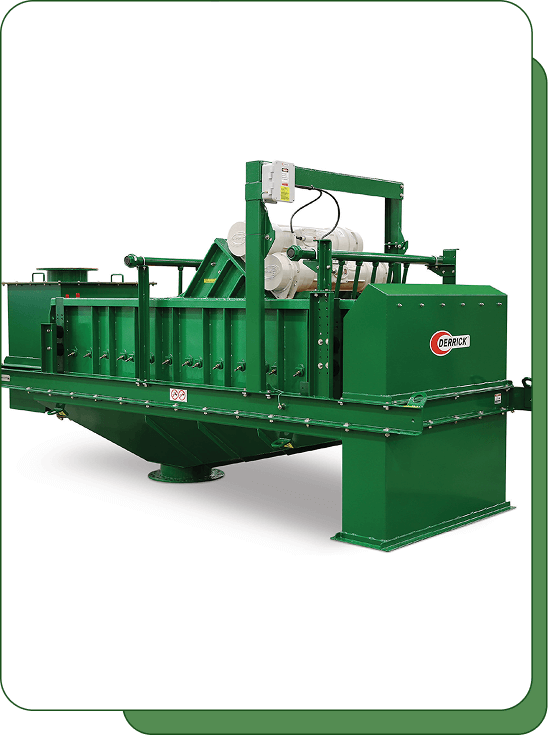

Linear Motion Machines

- Derrick® Linear Motion Machines are trusted across industries for their reliable performance in trash screening, dewatering, and wet scalping applications. With a proven track record in handling industrial minerals, precious metals, fertilizers, and even wastewater, these machines are available in various sizes and configurations to meet different screening capacity needs.

- Engineered for high-volume slurry processing, these machines perform best when handling slurry with a low percentage of oversize solids. When paired with high G-force Derrick vibratory motors and thickened slurry from hydrocyclone underflow, they efficiently remove free liquid from solids, making them perfect for dewatering tasks. Integrated small-diameter hydrocyclones and multi-nozzle spray bars allow the system to recover and dewater materials as fine as 400 mesh (38 microns).

- Derrick Linear Motion Machines are widely used in sand, coal, aggregate, concrete, graphite, and mining operations thanks to their low maintenance, low energy use, and quiet performance. Built for durability, all wear surfaces are protected with abrasion-resistant urethane coatings or rubber linings, ensuring long service life. Their open design allows easy visual inspection of screen panels and access to the feed box, making operation and maintenance both simple and efficient.

G-Vault Urethane Interstage Screen

- Derrick has spent decades innovating and perfecting upon this design and are proud to present the G-Vault® Urethane Interstage Screen as the gold standard for loaded carbon and resin circuits.

- The screens feature our unique thermoplastic urethane technology that’s supported by a robust but easily handled support structure. Non-blinding and abrasion resistant, enabling higher operation throughputs with longer lasting components that feature tapered openings, resistance to high temperatures, and an increased open area. Overall, this reliably improves gold recovery through decreased carbon losses and waste to tails.

- Each screen is built with a stainless steel frame and easily replaceable cartridge screens to facilitate faster assemblies and integration into existing circuits while reducing maintenance downtimes during plant operation. However, Derrick also offers the G-Vault® Complete Interstage Unit, a complete, custom fitted product that is engineered to improve overall process efficiency while still prioritizing operator safety and unit accessibility.

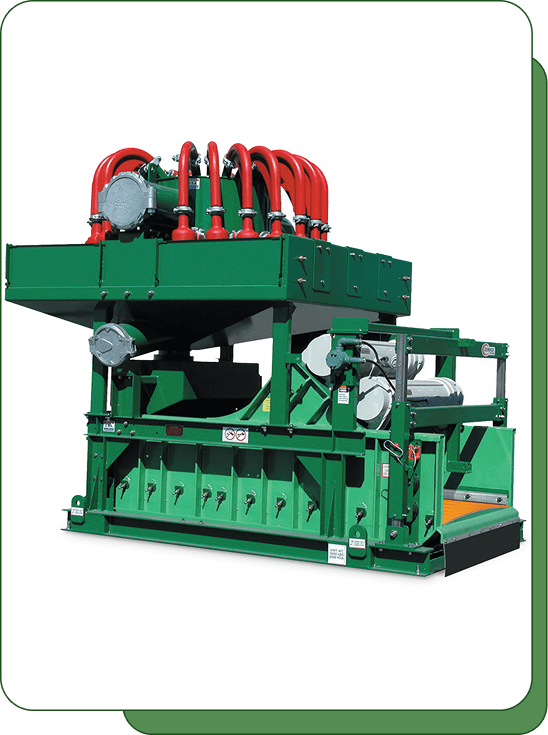

Hi-G Dewatering Machine

- The Derrick® HI-G® Dewatering Machine is a cost-effective, high-performance solution for separating and recovering fine solids—used globally in sand, aggregate, coal, concrete, graphite, and mining applications. It combines small-diameter hydrocyclones with a linear motion shaker, delivering powerful performance capable of recovering materials as fine as 325 mesh (45 microns).

- Equipped with two to twenty 4-inch hydrocyclones, each with its own shutoff valve, this machine efficiently removes silt-sized solids (20–74 microns) without the need for polymers or chemicals. Its dual 2.5 HP vibratory motors operate at 1,750 RPM, creating a precise motion that enhances separation efficiency. The unit features Polyweb® urethane screen panels, known for their high open area, non-blinding design, and long-lasting performance—making it ideal for continuous, high-capacity operations.

- Designed to recover up to 80% of the silts and ultra-fine sands that typically end up in settling ponds, the HI-G® machine helps reduce pond maintenance, lower costs, and even turn waste into a valuable product. With zero-maintenance motors, 3-panel and 4-panel options, and award-winning 24/7 field support, the Derrick HI-G® Dewatering Machine delivers performance you can count on—anytime, anywhere.

Maelgwyn Mineral Services provides a unique blend of skills in design, research and product development combined with considerable experience in mineral process operations, chemical and waste processing.

Products:

Aachen Shear Reactor

- The Aachen Shear Reactor is able to produce significantly higher dissolved oxygen levels whilst also introducing an element of shear to clean up mineral surfaces. It can be used to treat various materials such as refractory ores, oxides, transitional materials, and most especially gold tailings retreatment. It offers numerous benefits such as:

- Higher gold recoveries/lower residue grades

- Accelerated leach kinetics

- Reduced cyanide consumption

- Improved oxygen utilization

- Increased tonnages without compromising recovery

Imhoflot G-Cell

- The Imhoflot G-Cell is a new development in the pneumatic flotation technology that improves grade-recovery curve and increases the range of mineral particle sizes which can be recovered, both ultrafine and coarse.

- This is achieved through the higher energy dissipation for the bubble-particle attachment and the superior froth draining which reduces gangue entrainment.

Nasaco International Inc. is a company focusing on the flotation process and is run by metallurgical engineers. Their basic philosophy is to solve flotation and mineral processing problems chemically by providing collectors, frothers, depressants, and flocculants which are specific to different applications.

Borregaard is one of the leading providers of sustainable biochemical solutions across different industries worldwide. They are driven by their commitment to address and minimize environmental challenges by creating advanced biochemical counterparts on oil-based products. Bridging their impact on the mineral processing industry, they have established Pionera® BioPolymers that improves metal recoveries and plant process efficiency while minimizing environmental risks of traditional reagents.

MineFill Services is a global provider and recognized leader in mine backfill services to metal mining clients worldwide. Notable clients include major producers such as Newmont, Barrick and Rio Tinto as well as junior and intermediate producers of base metals and precious metals. Their clients span the globe from Australia to Africa, the Americas, Russia, China, and Europe.

ABEL develops and manufactures reciprocating positive displacement pumps for varying flow rates and pump pressures and specializes in diaphragm pumps. Depending on the design, they are suitable for abrasive, aggressive, and even shear-sensitive media. Solids handling pumps (for paste-like and non-Newtonian media) and high-pressure plunger pumps complete their range of products.

Gerhard Schaeffer offers solutions for Brewing and Distilling, Solar Farm Cleaning, and Environmental Process. Equipped with more than 15 years of experience in handling solutions of biomass and high solid sludges in wastewater, thermal powerplants, mining, dredging, AFR in cement, biogas, including pumping, storage, mixing, and crushing. Among his partners are Damen and Beijing ENSA Engineering.